Imperfect impressions due to casting defects or wear

Misread characters, resulting in tracking errors

Manual verification, which is time-consuming and prone to errors

Lack of centralized traceability, making audits and reviews difficult

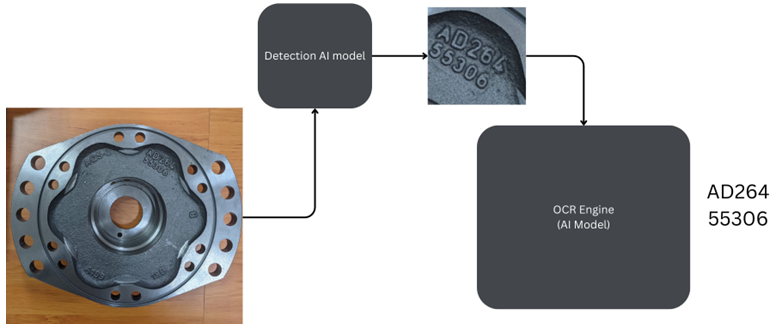

We developed an AI-driven Optical Character Recognition (OCR) system designed specifically for metal foundry environments. This automated system enhances traceability by detecting, correcting, and recording alphanumeric markings in real-time.

Image Capture: High-resolution cameras scan the metal surfaces to collect detailed images of the markings.

Preprocessing: AI algorithms enhance contrast, remove noise, and isolate characters to improve recognition accuracy.

OCR-Based Recognition: The system extracts alphanumeric characters from the impressions using computer vision.

Error Correction: AI-powered models automatically correct misread or partially damaged characters.

Database Storage: The corrected data is securely stored in a centralized database for real-time tracking and traceability.

Up to 95% accuracy in character recognition

Elimination of manual errors and faster verification

Seamless integration with existing tracking systems

Enhanced audit readiness and traceability compliance